During the production process, products are sampled to ensure that their appearance and performance meet inspection standards.

NewTechWood’s lab is where we uphold the highest standards of testing for our products. Equipped with cutting-edge technology and a team of experienced experts, we subject our products to comprehensive physical and chemical analyses, evaluating factors such as durability, dimensional stability, and impact resistance. Through continuous research and development, we strive for a continuous improvement, raising the bar for composite standards.

534

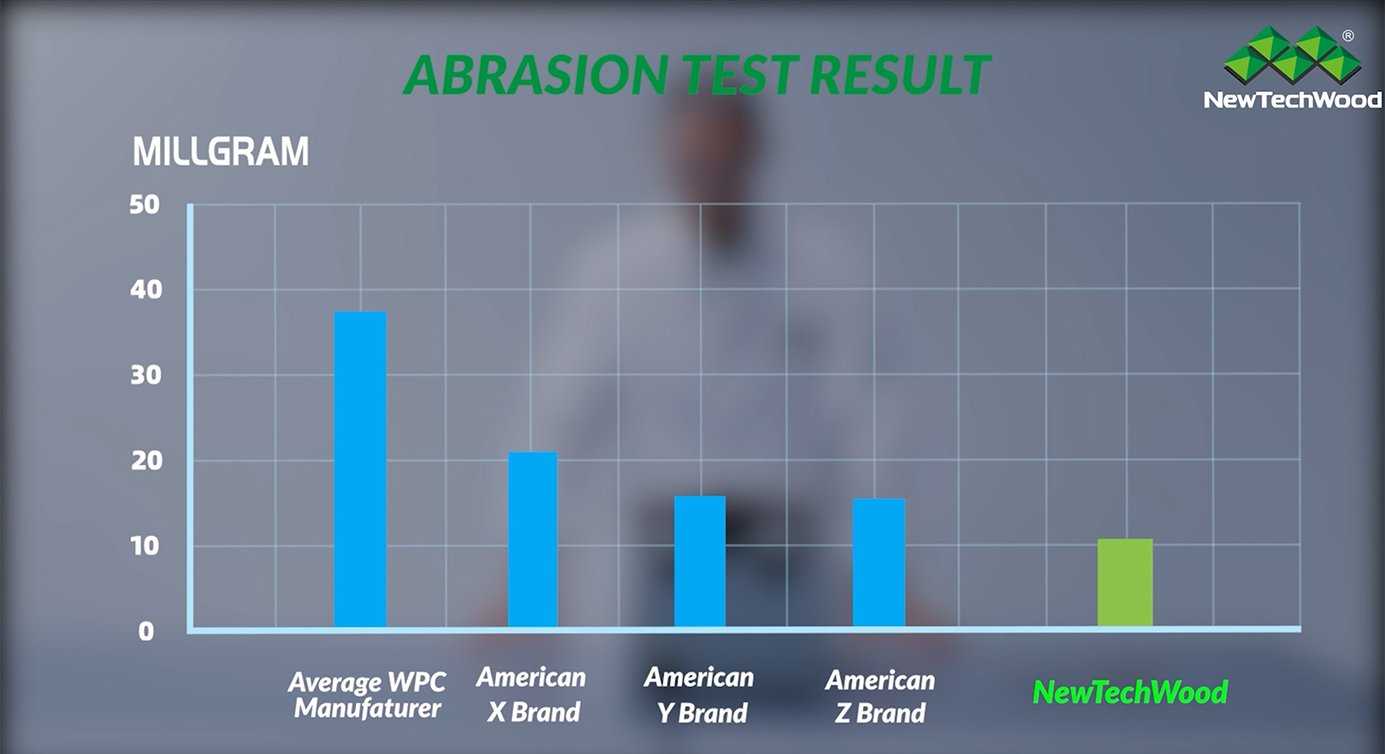

Abrasion Test

Rotational numbers

Test Data

1000

Kick Board Test

22 Joules 1000 shocks

Test Data

5100

N

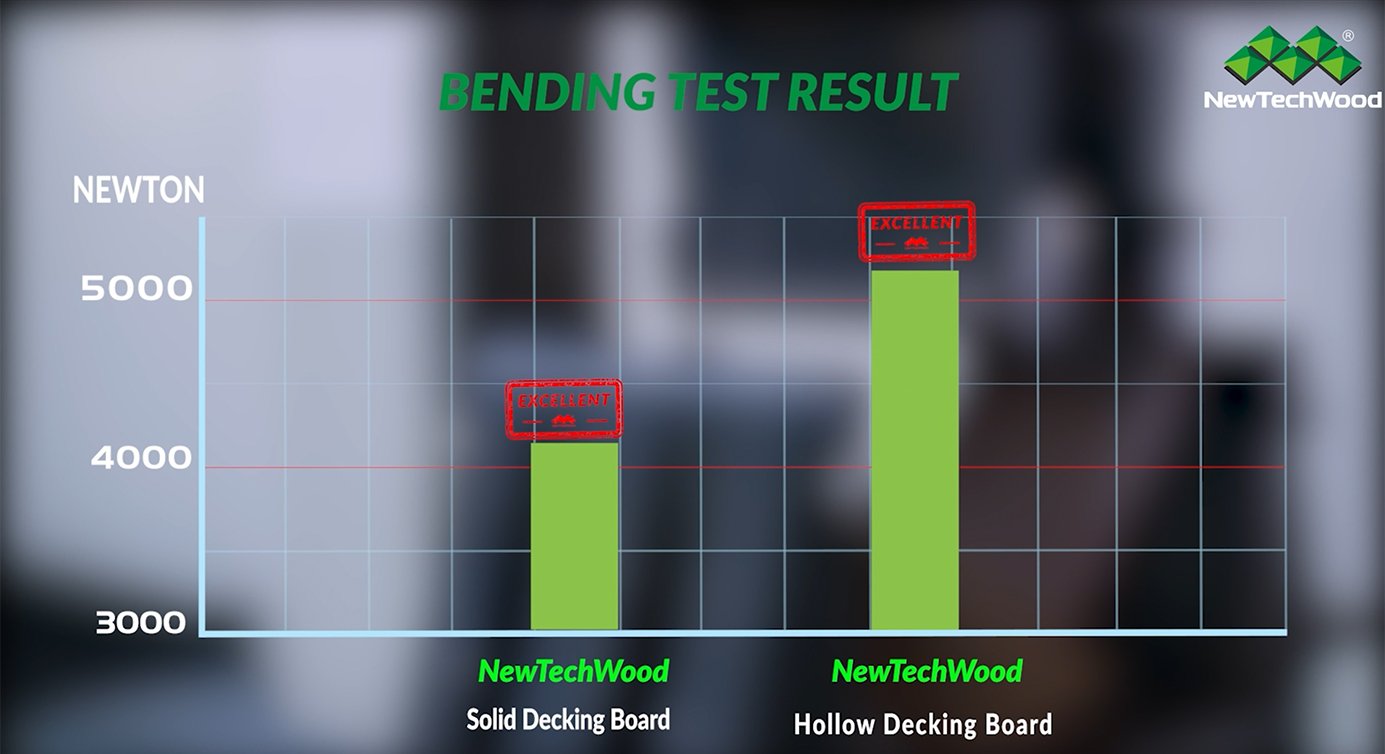

Bending Test

Solid Decking Board

Test Data

4200

N

Bending Test

Hollow Decking Board

Test Data

100

Boiling Test

Boiling for 100 hours

Test Data

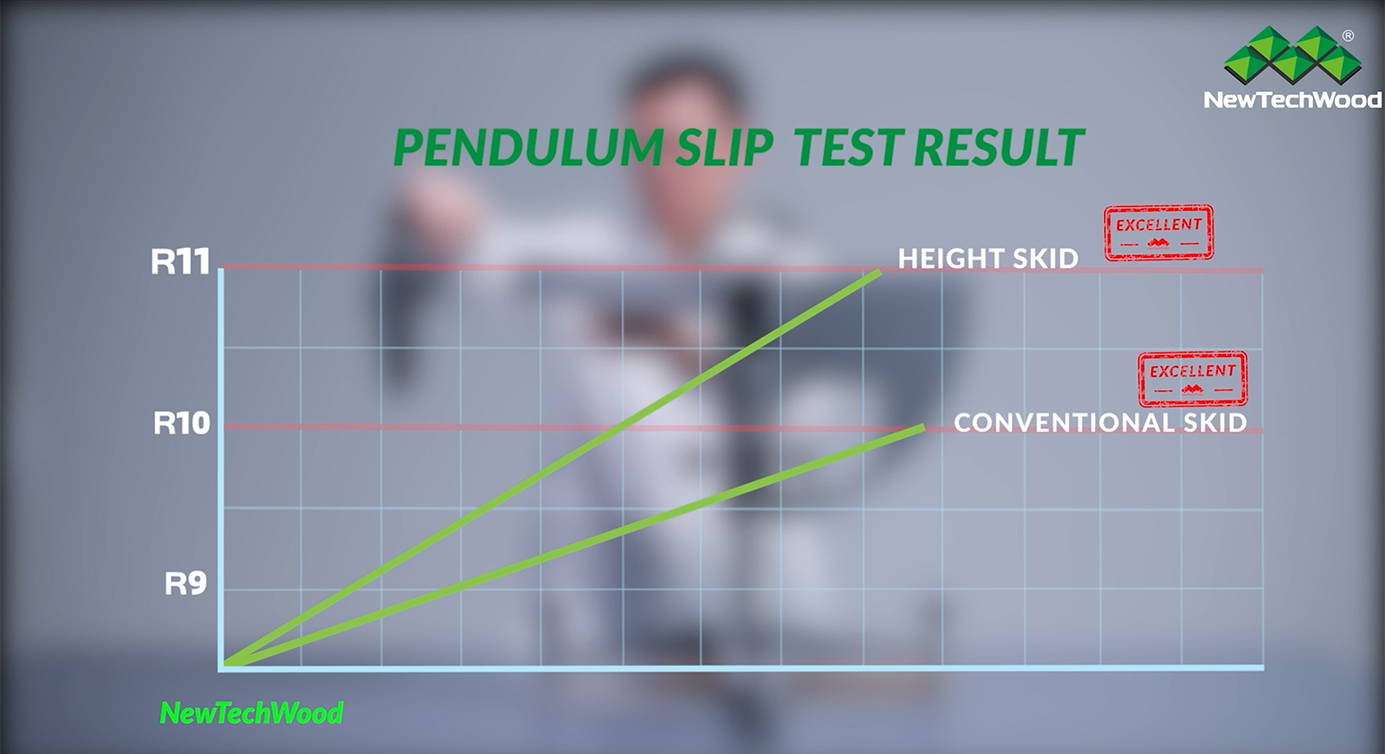

The pendulum slip resistance test measures the slip resistance ofa floor surface by replicating the interaction between a moving pedestriain heel and static surface. The Pendulum has a swinging arm with a rubber slider attached to the heel cInf an imitation foot, which sits at the bottom of the arm.

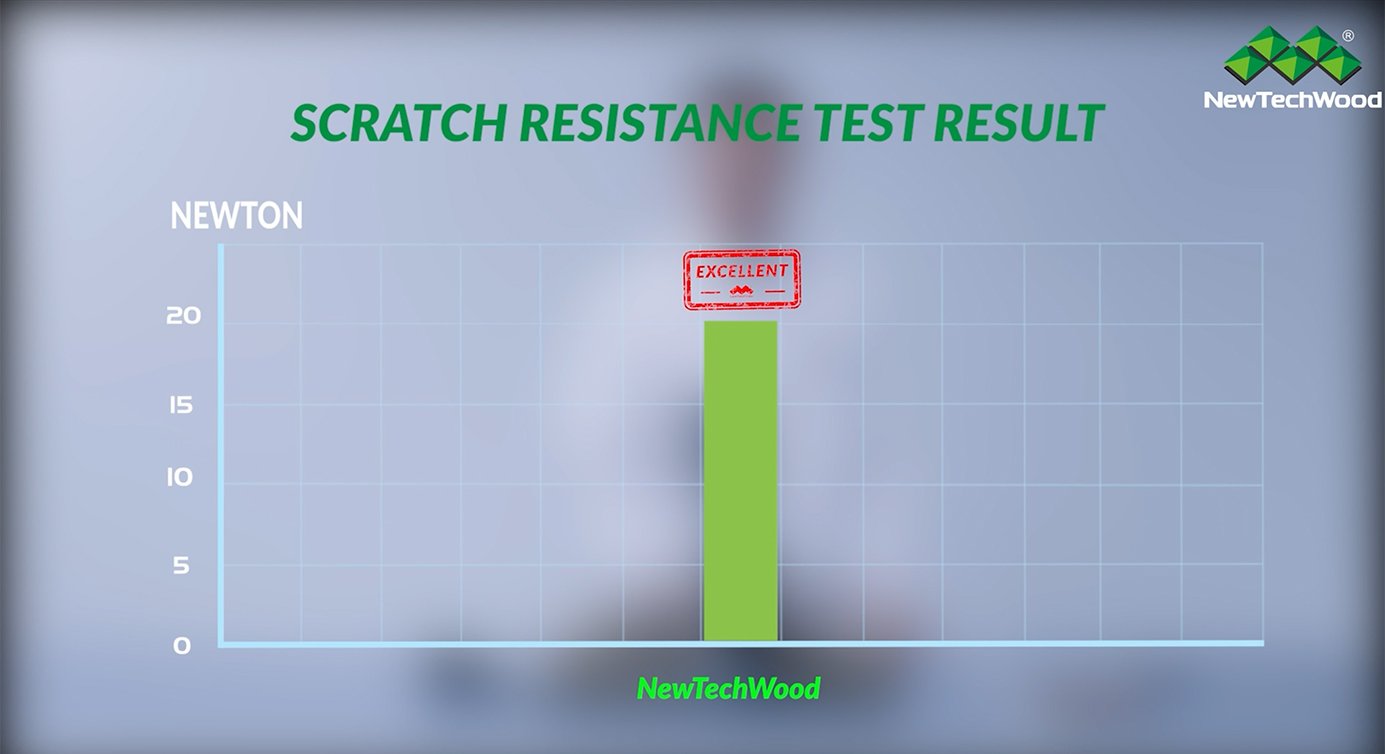

Scratch Resistance Test is to measure the relative resistance or susceptibility of a material surface to scratching, marring, gouging, scraping, engraving and other similar physical damage not classifed as ordinary wear.

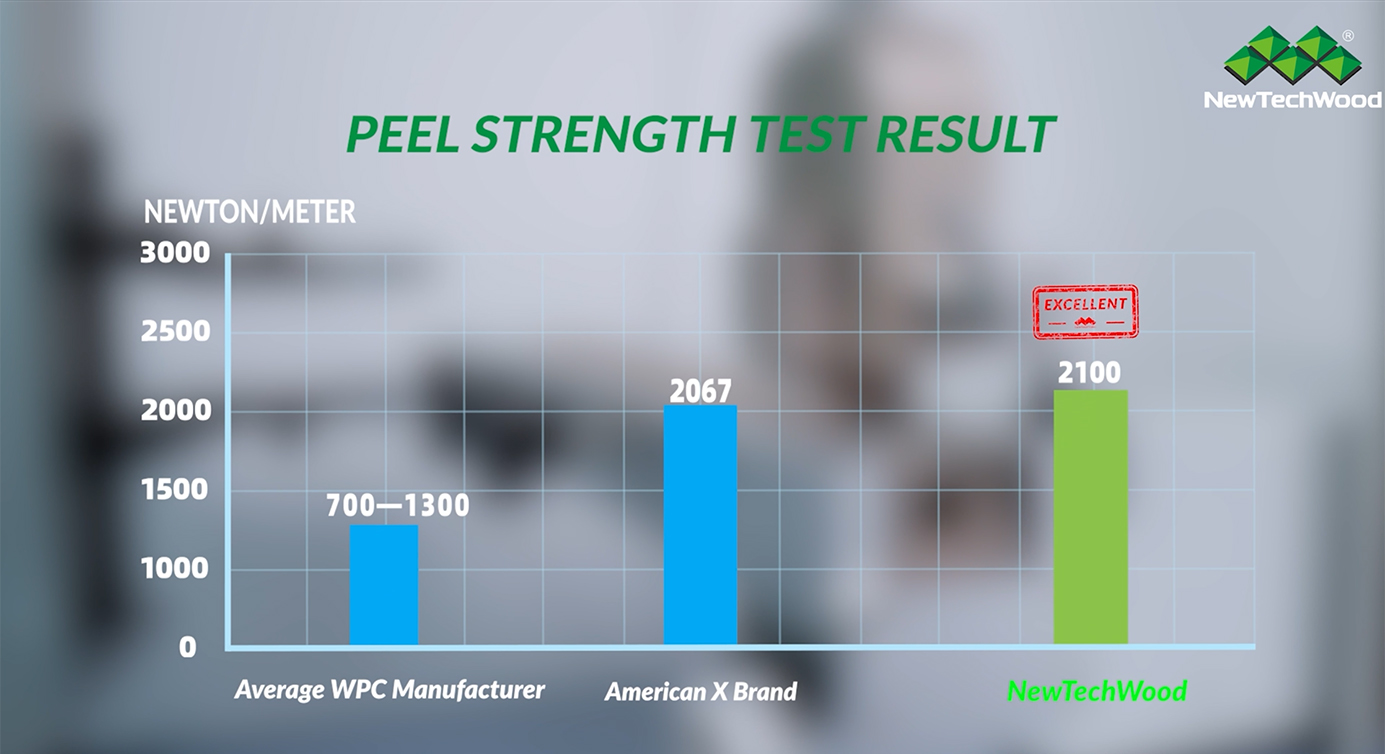

Peel strength testing determines the adhesive strength of materials that have been bonded together. The cap materials are peeled apart at a constant speed and the strength of the force needed to separate the cap materials from the core is calculated along with the width of the bond surface to determine the peel strength.

Taber abrasion test consists of a disk-shaped specimen that is placed in constant contact with an abrasive wheel, using predetermined forces to a speecified number of cycles to determine wear.

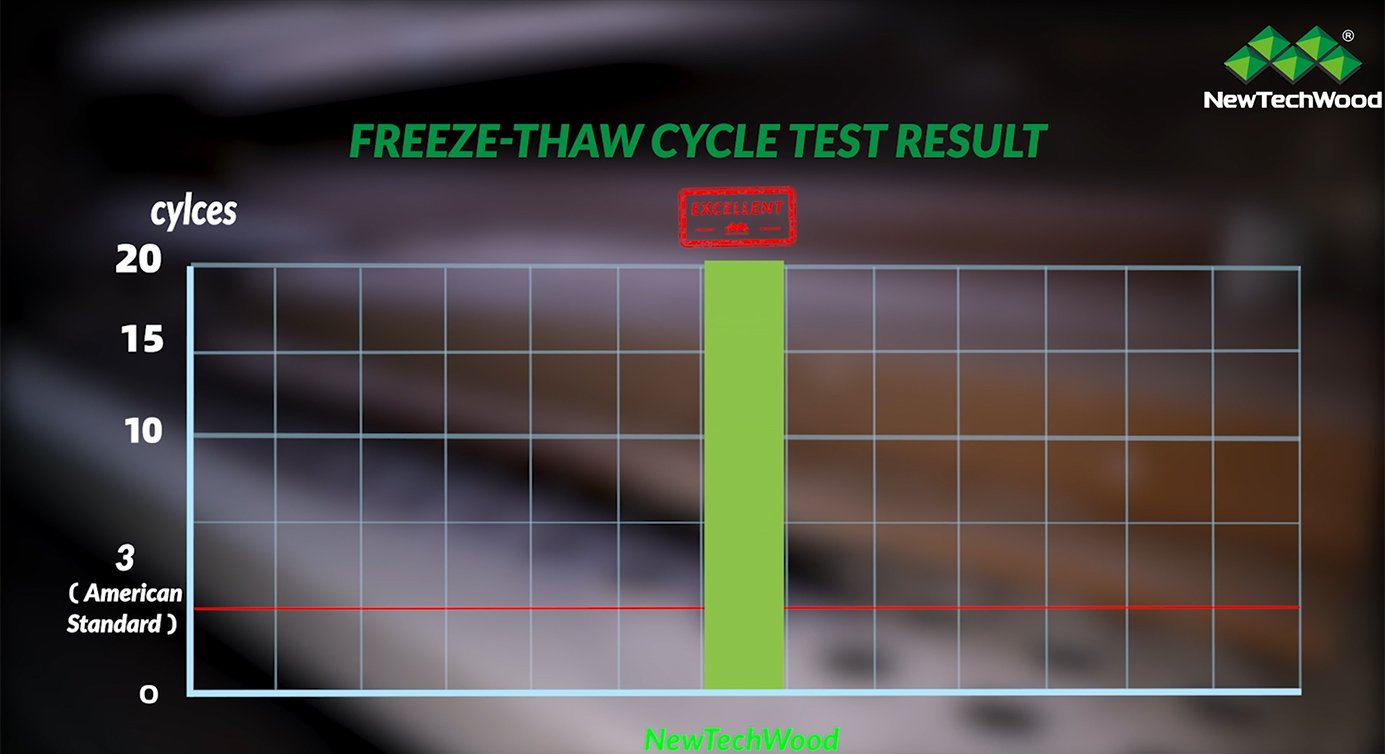

The freeze-thaw cycle test determines the stability of theproducts under various conditions. This type of test puts the product through a sseries of extreme, rapid temperature changes that it may encounter during normal usage.

Bending test is conducted by placing a piece of product across a span and pushing down along the span to bend the material until failure. Bending test reveais the elastic modulus of bending, flexural stress, and flexural strain of a material.